EFI Mezzera Pre and Post Treatment Machines

The EFI Mezzera high-efficiency fabric preparation and finishing lines improve all the characteristics of the finished garment for textile perfection.

EFI Mezzera MERCERIZING

Working widths

1803 to 3404 mm

Speed

30 to 60 m/min

Assembly type

modular

Fabric type

woven and knitted

EFI Mezzera SINGEING

Speed

up to 120 m/min

Burners

2 - movable with variable intensities

Temp. control

thermo regulator

Fabric type

woven

EFI Mezzera ESSETEX

Treatment chamber

single or double drum

Running mode

tensionless

Fabric type

woven and knitted

EFI Mezzera CONCORD

Working temp.

up to 98 °C

Speed

up to 100 m/min

Water consumption

8 to 15 l/kg

Chemical dosage

automatic

Fabric type

woven and knitted

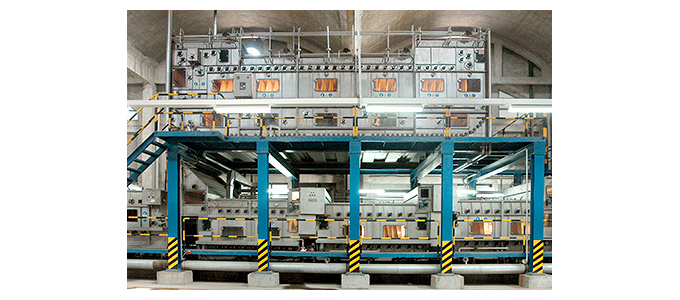

EFI Mezzera JIGGER

Working widths

1803 to 3607 mm

Mechanical speeds

30 to 150 m/min

Roll batch diameter

305 to 1397 mm

Driver

inverter

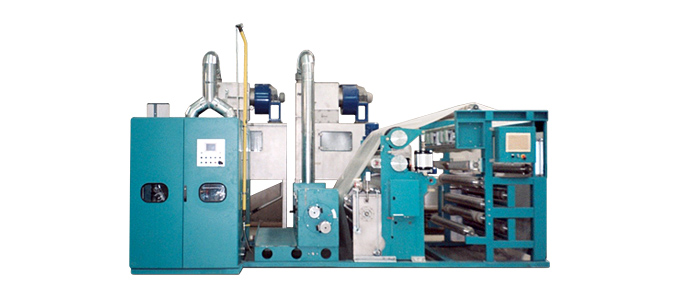

EFI Mezzera LOOP/SLASHER

Working width

1600 to 2007 mm

Max. speed

45 m/min

Oxidation

55 min

Max. dips

10 indigo in 3 boxes

Indigo bath volume

4000 litres

Equipped

Nitrogen reactor

EFI Mezzera ROPE

Working width

1397 to 2794 mm

Max. speed

50 m/min

Oxidation

60 min

Max. dips

14 indigo

Counts

Ne 6/1 to Ne 30/1

Equipped

Nitrogen reactor