Duplo integration

Reduce turnaround time by automating steps from prepress to finishing

Save up to 70% in setup time and produce more profitable jobs with Fiery Driven™ print engines and a wide range of Duplo finishers.

Video: Automate the job preparation process from prepress to post press

Overview

Fiery and Duplo have collaborated to develop several time-saving integrations between Fiery Driven print engines, Fiery workflow software, and Duplo finishers.

Slitters, cutters & creasers

DC-618 / DC-646 / DC-648 / DC-746

Save up to 70% in setup time by automating job prep and eliminating manual data entry with Fiery Impose in Fiery Driven print environments. The integration between Fiery Impose and Duplo’s Slitter/Cutter/Creasers offers timesaving workflows that can be applied to both common and custom layout jobs.

Duplo provides imposition templates — for the most common jobs such as business cards or postcards — to use in Fiery Impose that match the finishing templates on the Duplo DC-618, DC-646, and DC-746 Slitter/Cutter/Creasers. The finishing templates come pre-set with measurements for the margins and gutters as well as finishing sizes. The templates use barcodes and registration marks that let the Slitter/Cutter/Creaser adjust automatically without intervention.

For custom layout jobs using the Duplo DC-646 and DC-746, users can create the new layout file on the Duplo PC controller, import it in Fiery Impose and instantly see a visual preview of finishing lines to quickly verify job designs before printing. Users can save the layout as a Fiery Impose template to automate the same type of job in the future using one-step automated workflows such as Fiery Hot Folders, Fiery Presets, Fiery JobFlow or Virtual Printers. This automated solution reduces human setup errors and accelerates turnaround times.

For custom layout jobs using the Duplo DC-618 and DC-648, users can easily set up an imposition layout entirely within Fiery Impose including cut, crease, and perforation finishing marks for even more time savings. With this advanced finishing integration, there is no longer a need to set up a finishing layout on the Duplo controller and import it into Impose. Fiery Impose has built-in knowledge of the DC-618 and DC-648 configuration options and constraints. This workflow accelerates production turnaround time while eliminating operator touchpoints and errors from incompatible layouts.

Benefits

- Reduce production bottlenecks by eliminating manual processes

- More efficient production workflows

- Visual preview of finishing lines before printing reduces errors

Resources – Duplo DC-616, DC-618, DC-646, DC-648, and DC-746

- How-to guide: automate offline finishing with Duplo finishers

- Express video part 1: Use pre-made templates to automate most common jobs

- Express video part 2: Create a custom layout to automate a coupon job

- Resource guide: Fiery Impose integration with Duplo Slitter/Cutter/Creasers

- Fiery Impose and Duplo remote integration service

Resources – Duplo DC-618

- Express video part 3: Automate offline finishers with Duplo DC-618

- Demo video: Create a custom imposition layout with finishing marks for Duplo DC-618

Resources – Duplo DC-648

Spot UV coaters

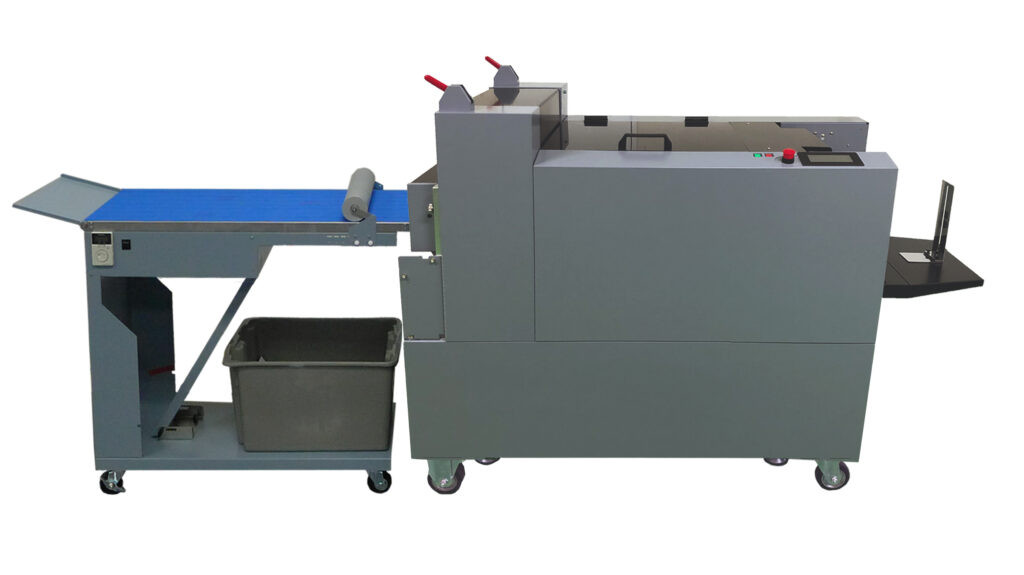

DDC-810

With Fiery JobFlow, users now have a end-to-end automated workflow for digital embellishment on the Duplo DDC-810 Raised Spot UV Coater. Seven manual file preparation steps can now be accomplished in one step, including creation of separate CMYK and spot UV files, page imposition, application of registration marks and barcodes, and submission of CMYK and spot UV files to a Fiery Driven™ printer and the DDC-810, respectively. The Fiery integration also leverages existing Duplo barcode support for additional finishing on Duplo DC-746 or DC-646 Slitter/Cutter/Creasers. Print service providers can save up to 70% of the finisher setup time by using a barcode produced by Fiery Impose software to automate the setup.

Benefits

- Streamlined prepress processes and lower labor costs

- Increased profit potential by efficient production of high-value, embellished jobs

- Reduce production bottlenecks by eliminating manual processes

Resources

Die cutters

UD-300 / UD-310 / DPC-400

With Fiery JobFlow, users can automatically perform job prep functions on the Duplo UD-300 Rotary Die Cutter, UD-310 Rotary Die Cutter, or the DPC-400 Digital Die Cutter such as auto-rotation of pages and adding registration marks.

Benefits

- Reduce production bottlenecks by eliminating manual processes

- More efficient production workflows