126 in

Print width

2,828 ft² (74 boards)/hr

Max. productivity

1200 dpi

Resolution

CMYKcmyk + 2 white

Colors

CMYKcmyk + W + Clear, CMYK x 2 + 2W, CMYK x 2 + Clear

Optional configurations

Take your business higher with a powerful competitive edge

The EFI™ VUTEk® h3+ hybrid flatbed/roll-fed inkjet printer will take your business higher in terms of productivity, print quality, reliability, capability, and profits. All with the ease of use and LED environmentally friendly benefits you expect from an industrial-built VUTEk LED hybrid printer from EFI.

Book a Demo

Offer customers more high-value applications

Highlights

Versatile hybrid platform

Board, sheet, or roll-to-roll printing on media up to 2 inches thick in one innovative footprint. Includes media hold-down rollers for uneven or curled media.

Production-level printing

Three rows of printheads for eight-color production printing up to 950 ft² (23 boards) per hour. Switch to fast-four-color printing (optional) quickly and easily in the operator software to accommodate burst capacity. Includes skip white functionality in x and y directions.

Brilliant imaging

Four (optional) or eight colors plus white, optional clear ink, and UltraDrop™ Technology 7pL grayscale printheads for up to 1200 dpi resolution.

White ink and multilayer printing

EFI white ink leads the industry in brightness and opacity and can be imaged like any color or using multilayer printing with up to nine layers in a single pass.

Precision printing

Automated table and carriage alignment, magnetic linear drive control and step mechanics and electronics, and a camera-based vision system for subpixel alignment, printhead density balance, and step and bi-directional setup.

Efficient production

Mechanical crash detection stops, wrinkle detection, and media height measurement help prevent job stoppages and wasted ink and media.

Industry-leading LED technology

Extend your range of supported substrates, increase uptime, reduce operating costs, and move towards more sustainable production with low VOCs, lower energy consumption, and less waste and consumables.

Innovative ink delivery

Ink loading with a drop-in design eliminates wasted ink and the need to manage leftover ink. The system features fill-while-printing functionality and an ink security system with low ink, color, and location indicators.

Genuine EFI Inks

Expanded gamut CMYK pigments for world-class Pantone® matching. EFI pigment dispersions ensure optimized size and concentration for best-in-class ink stability.

Fiery Driven

Fiery® proServer Premium digital front end with color management workflow and RIP optimized for EFI VUTEk printers.

Learn more >

Fiery IQ

Use the Fiery IQ™ suite of cloud applications to connect your people, processes, and print devices to make better data-driven decisions that improve your ROI, minimize cost, maximize profit, and boost your revenue.

Learn more >

Print and media handling options

EFI UltraClear Coat provides a more flexible cure and can be used for decorative applications as well as for a final protective coating. It prints inline, simultaneously with the image, saving time versus using a separate offline coating system, and in gloss* or matte finishes.

* Use Gloss print mode for full protection

EFI VUTEk Endura Clear Ink – Enhance an entire image (full flood) or selected areas (spot) to add extra pop to colors or special effects to graphics. Endura clear ink is printed in line with the other colors and provides a hard surface cure with a gloss finish.

EFI Transform-TF Inks – next-generation, LED-curable digital inks formulated for first- and second-surface interior and exterior and non-backlit and backlit applications where common thermoforming is specified. Transform-TF inks exhibit outstanding elongation characteristics while maintaining excellent adhesion and opacity and provide ideal characteristics for heat bending and routing of acrylic sheets with no chipping or loss of adhesion. And since Transform-TF inks adhere to a broad range of materials, applications go well beyond thermoforming.

Gloss+ print mode – use this innovative print mode to add a flood or selective gloss effect to graphic prints without the use of clear ink. It’s the perfect way to add value to short-run, specialty jobs.

Double vacuum kit – get better control of thicker media and thin, light-edged materials by doubling the vacuum strength on the print table.

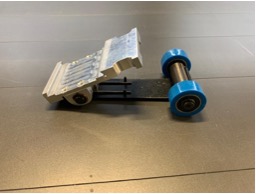

Media handling accessories

All new media hold-down rollers mount to existing MEG rails and the spring rollers force media into the vacuum, often eliminating the need for MEG skis.

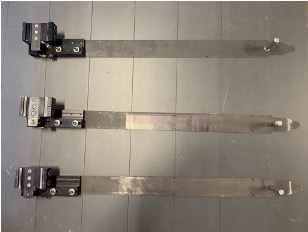

Media Edge Guide (MEG) skis are available in 0.063 in, 0.094 in, and 0.012 in thicknesses.

Tables

- Standard flat table: 126 in x 60 in (3.2 m x 1.5 m)

- Narrow depth flat table: 126 in x 20 in (3.2 m x 0.5 m)

- Table with rollers for heavy substrates: 126 in x 60 in (3.2 x 1.5 m)

- U-shaped walk-in table designed for small rigid media: 126 in x 60 in (3.2 x 1.5 m)

- U-shaped walk-in table with rollers designed for small, heavier rigid media: 126 in x 60 in (3.2 x 1.5 m)

Automation options

- 3/4 automated media loading

- 3/4 transition table

- 3/4 automated stacking

Roll-to-roll Media Handling Options

- Standard unwinders/rewinders

- Max. roll weight 126 in (320 cm) air core: 400 lb (181.4 kg)

- Max. roll weight 54 in (137 cm) air core: 170 lb (77.1 kg)

- Max. roll diameter: 12 in (304.8 mm)

- Elevated dual-drive unwinders/rewinders

- Max. roll weight 126 in (320 cm) air core: 400 lb (181.4 kg)

- Max. roll weight 54 in (137 cm) air core: 170 lb (77.1 kg)

- Max. roll diameter: 12 in (304.8 mm)

- Super-duty unwinders/rewinders

- Max. roll weight 3 in air core: 705 lb (320 kg)

- Max. roll weight 6 in air core: 1,763 lb (800 kg)

- Max. roll diameter: 27.5 in (700 mm)

- Super-duty dual-drive unwinders/rewinders

- 126 inch- (320 cm-) wide max. roll weight 3-inch full-width air core: 705 lb (320 kg)

- 60 inch- (152.4 cm-) wide max. roll weight 3-inch full-width air core: 600 lb (272 kg)

- 126 inch- (320 cm-) wide max. roll weight 6-inch full-width air core: 2,200 lb (1000 kg)

- 60 inch- (152.4 cm-) wide max. roll weight 6-inch full-width air core: 1.100 lb (500 kg)

- 60 inch- (152.4 cm-) wide max. roll weight per side 3-inch dual drive air core: 880 lb (400 kg)

- 60 inch- (152.4 cm-) wide max. roll weight per side 6-inch dual drive air core: 1,100 lb (500 kg)

- Max. roll diameter: 59 in (1500 mm)

- Min. roll width: 24 in (610 mm)

- Max. roll width on full-width air core: 126 in (3200 mm)

Resources

The Ultimate Guide for White, Clear, and Multi-layer Applications

This guide will help you create new ways print can be used to break through and stand out in a big way.