28 in

Max. print width

up to 164 ft/min

Productivity

up to 360 dpi

Resolution

up to 8

Printing bars

The power of digital printing

comes to tableware decoration

Digital inkjet printing is a new option for tableware decoration that allows you to print directly to ceramic plates and dishes. Inkjet is a contactless technology that does not require plates or silicone pads and prints edge-to-edge on reliefs. The EFI Cubik industrial digital inkjet ecosystem makes the adoption of inkjet printing technology easy with all the elements needed for the brilliant decoration of tableware.

Book a Demo

Turn tableware into a profitable

opportunity

Highlights

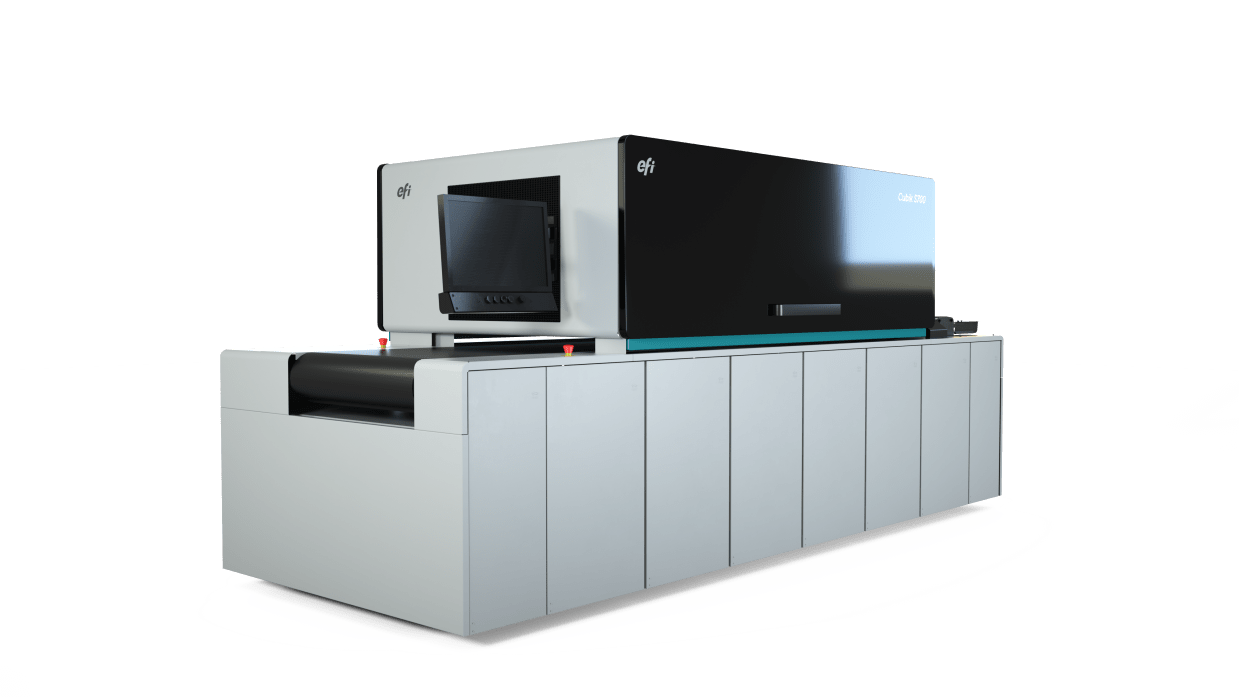

Single-pass inkjet printer

Made for industrial environments and 24/7 operation. Decorate pieces up to 1.18 inches high. The optional artificial vision system at the entrance of the printer adjusts the graphic to the exact position of the plate and manages different shapes (round, oval, and rectangular) with ease.

Genuine EFI Inks

Colors available are blue, cyan, red-brown, yellow, ochre, black, and white for a wide color range and defined decorations.

Fiery proServer for Ceramics

Fiery® proServer for Ceramics is a dedicated color management solution for digital ceramic tile decoration that produces accurate color results with the lowest ink costs, independent of final production conditions.