Power Tools to boost your

capabilities and profits

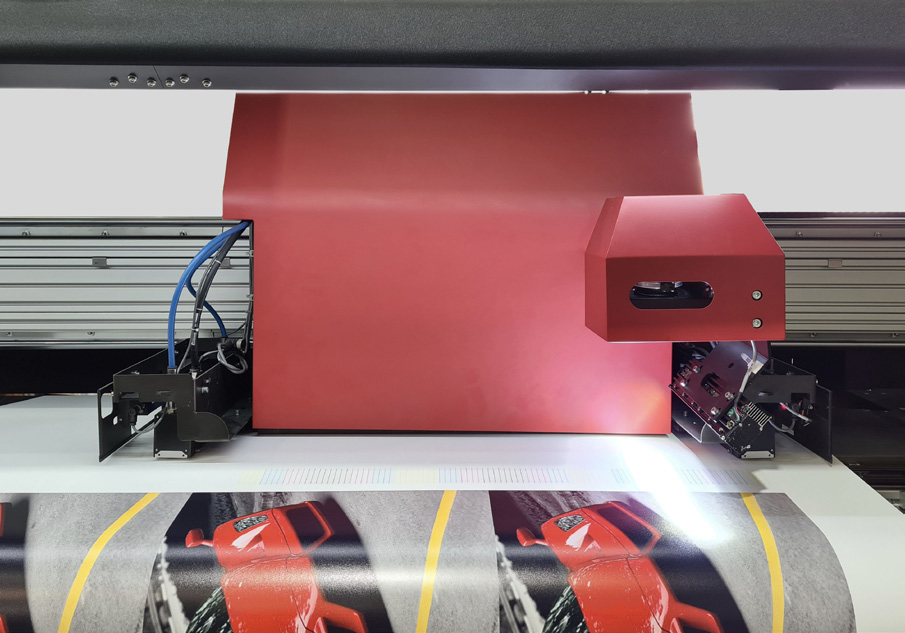

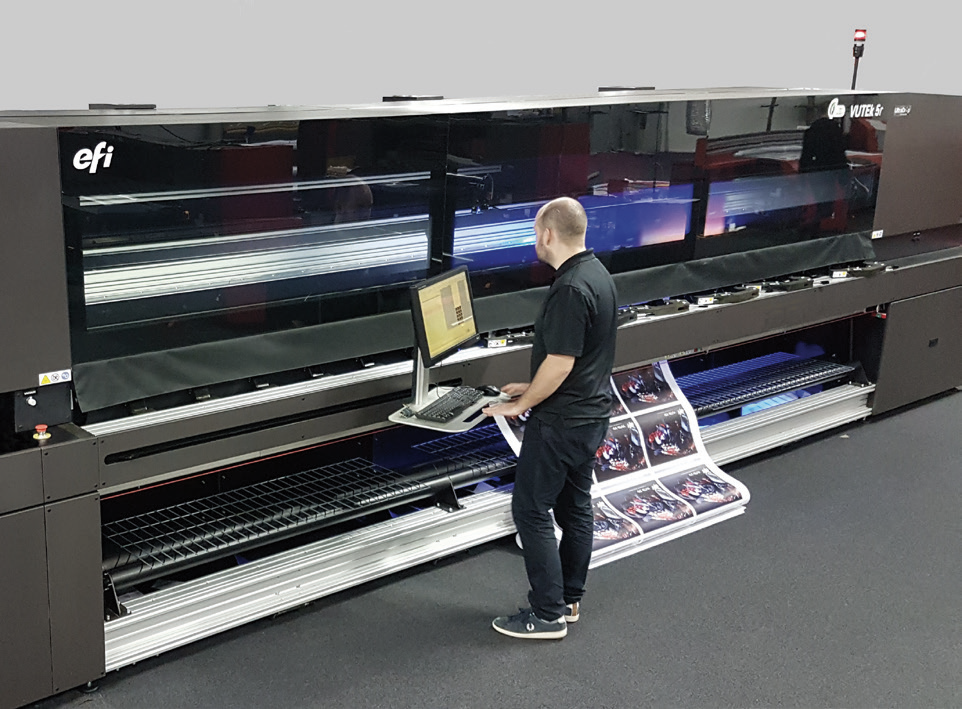

EFI™ superwide- and wide-format roll-to-roll LED printers feature a rich collection of value-added options and software that transform them into all-in-one, multi-purpose platforms – expanding your capabilities, application offerings, and profit opportunities.

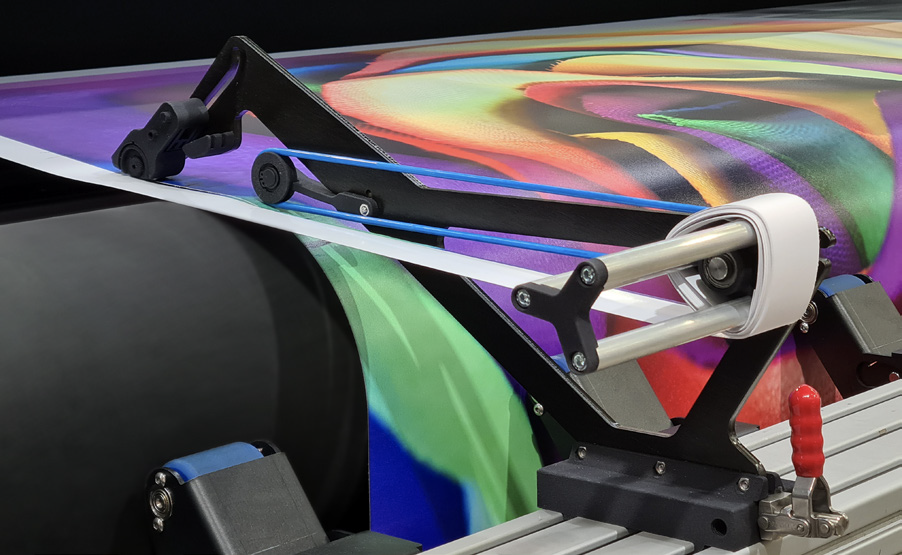

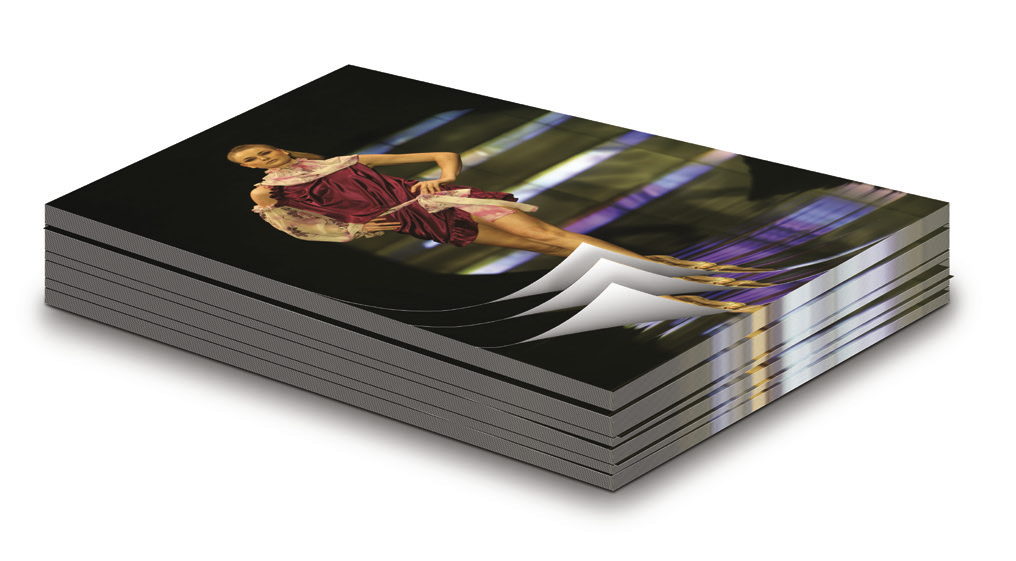

Inline Finishing Workflow

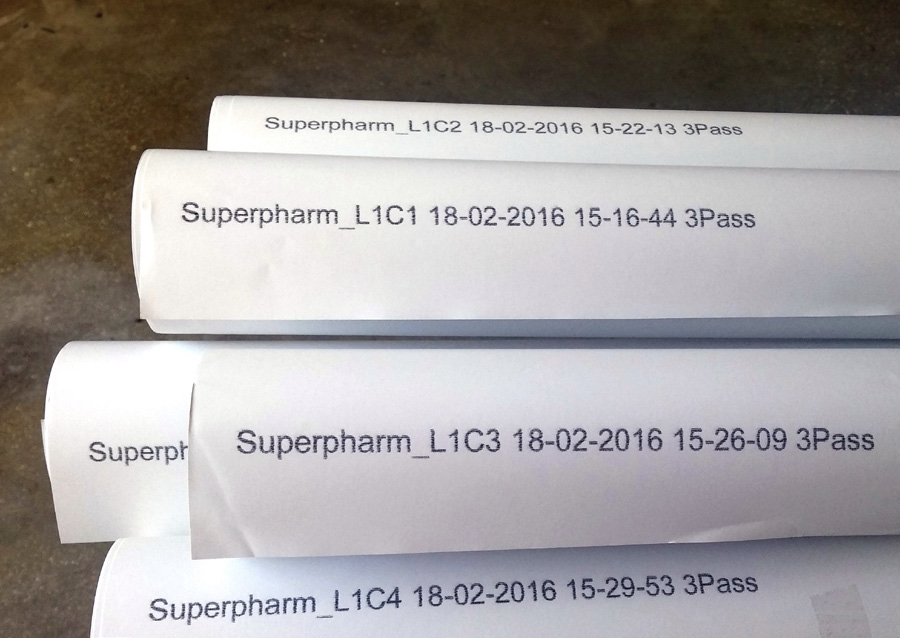

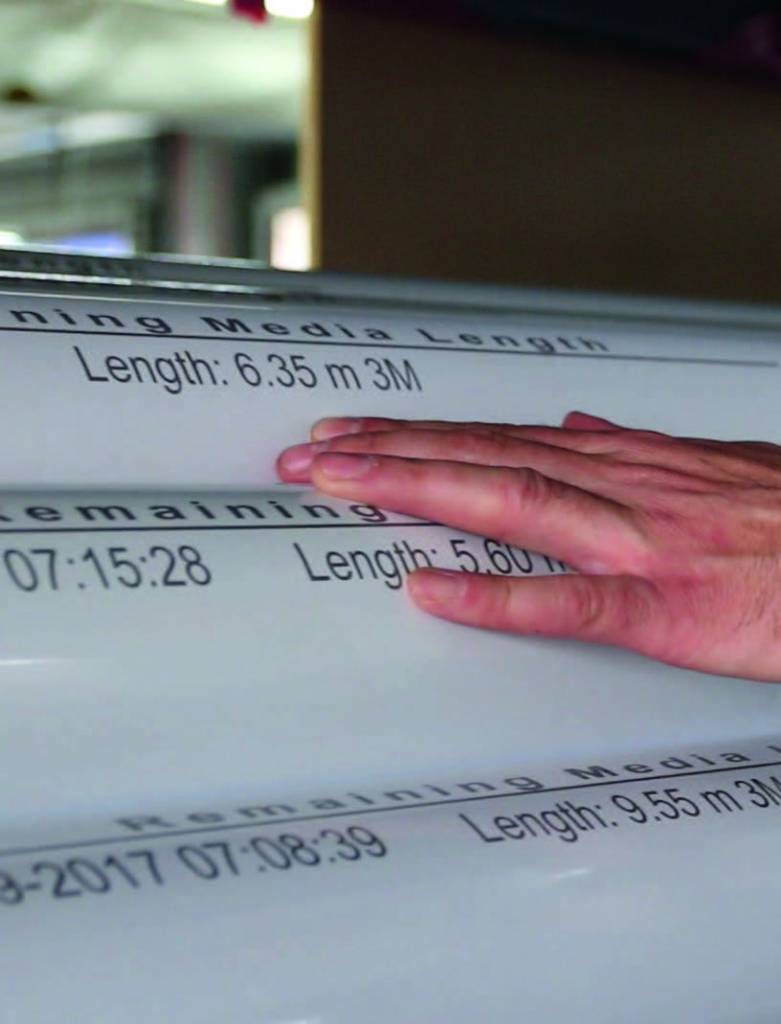

EFI’s unique inline finishing workflow automates the complete printing and finishing process on the fly and in a single system. The system can include all or any combination of the following components: printing, automatic inspection of printed output, printing customer information on the back of the media, vertical slitting and trimming, horizontal cutting, and rolling of the final graphics into scrolls and taping the edges with labels with printed job information.

Inline finishing workflow benefits

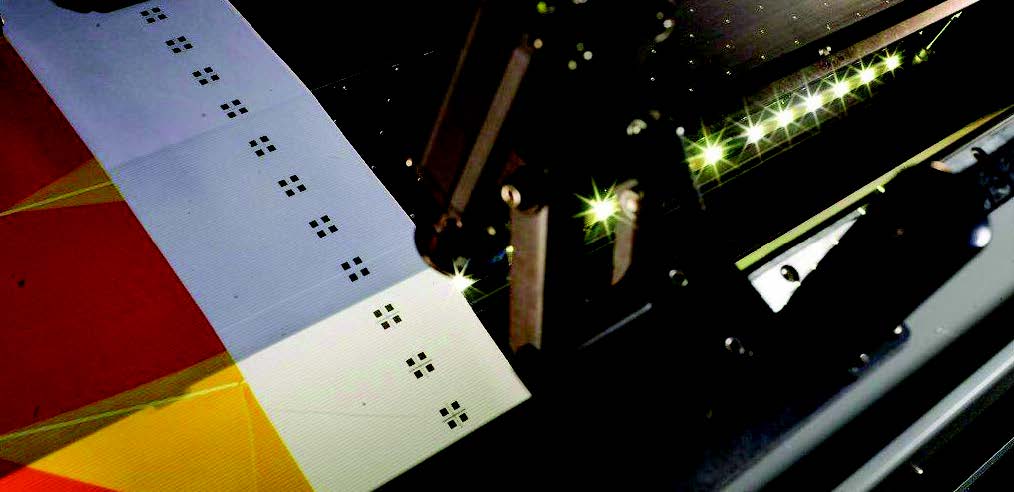

Inspect

Label

Y-slit and X-cut

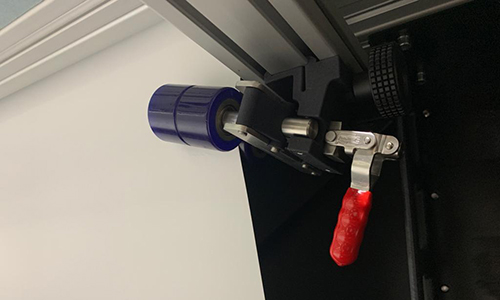

Roll & Tape

- Saves valuable time and eliminates bottlenecks at finishing stations

- Replaces additional expensive finishing equipment and saves valuable floor space

- Ensures perfect print quality with minimal operator intervention

- Prevents finishing, shipping, and installation errors

- Increases yield

Looking for additional information?

Making a decision to transform your business is not easy. We’ve helped thousands of customers select the right digital printing technology to increase profits, cut costs, improve productivity, and optimize efficiency. We’re always ready to talk about your goals and how we can help. Complete the form and we’ll be in touch soon.

Thank you for your interest in EFI.

One of our representatives will contact you shortly.