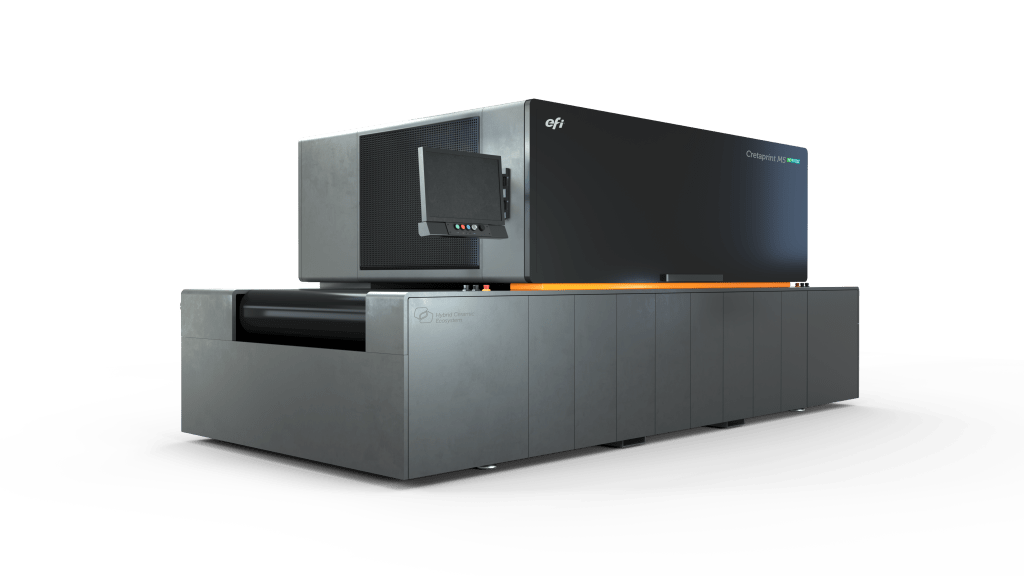

90.5 in

Max. print width

up to 197 ft/min

Productivity

up to 360 dpi

Resolution

up to 12

Printing bars

The only ceramic ecosystem of its kind

EFI™ offers a complete ceramic decoration ecosystem designed for the specific needs of the industry. EFI’s ceramic tile printers, ceramic inks and glazes, color management software, and a complete service program will help you drive process efficiencies, increase productivity and quality, and meet environmental requirements.

Book a Demo

HYBRID CERAMIC ECOSYSTEM

Offer customers more high-value applications

Highlights

Hybrid technology

The only hybrid inkjet printers for ceramics that can work with water-friendly inks and eco-solvent inks. Six EFI Cretaprint printer models to choose from with up to 12 printing bars.

Easy to use

The multi-language and touch screen user interface makes operation intuitive with direct access to main functions, printing bars, and the transport system. The alarm status is always on the screen.

5th generation software

Supports many user applications, such as:

• TAS for automatic tone adjustment

• Fine tunning for density balancing

• Nozzle out for clogged nozzle compensation

• SCADA application for Industry 4.0

• EFI Go to monitor your printers from mobile devices

• ID printing for master tiles and traceability

Communication 4.0

This optional application for the EFI Cretaprint printer software provides interfaces with a standard Modbus protocol to allow third-party SCADAs and PLCs access to printer parameters, such as machine status, models printed on each line, tile characteristics, ink levels, printed feet, and alarms.

Configurable service program

A configurable service program that includes technical assistance, preventive maintenance, ceramic design, and ink plans.

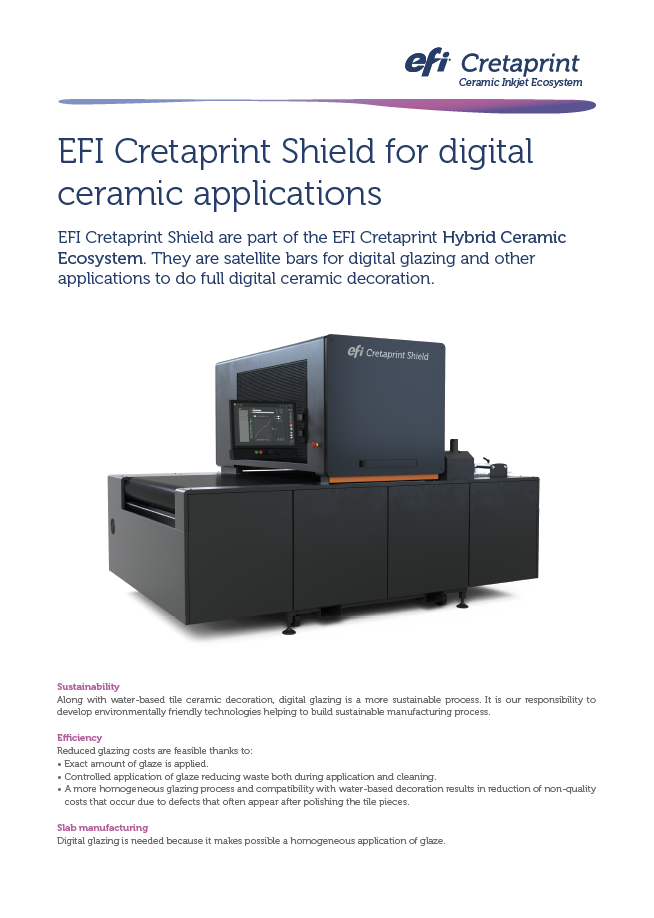

EFI Cretaprint Shield

Complement your equipment by placing satellite EFI Cretaprint Shield printers before tile printing to apply digital glaze, or post tile decoration to apply glues and other effects.

Fiery Driven

EFI Fiery proServer for ceramics. – the world’s first color management software for tile decoration.

Resources

EFI Cretaprint Shield

Complement your equipment by placing satellite EFI Cretaprint printers prior to tile printing to apply digital glaze, or post tile decoration to apply glues and other effects.

Genuine EFI Cretacolor Inks Brochure

Genuine EFI™ Cretacolor Inks are an essential element in high-quality, consistent, and reliable ceramic tile decoration.